De ratione cuiusque structural fabrica filum trahens machina

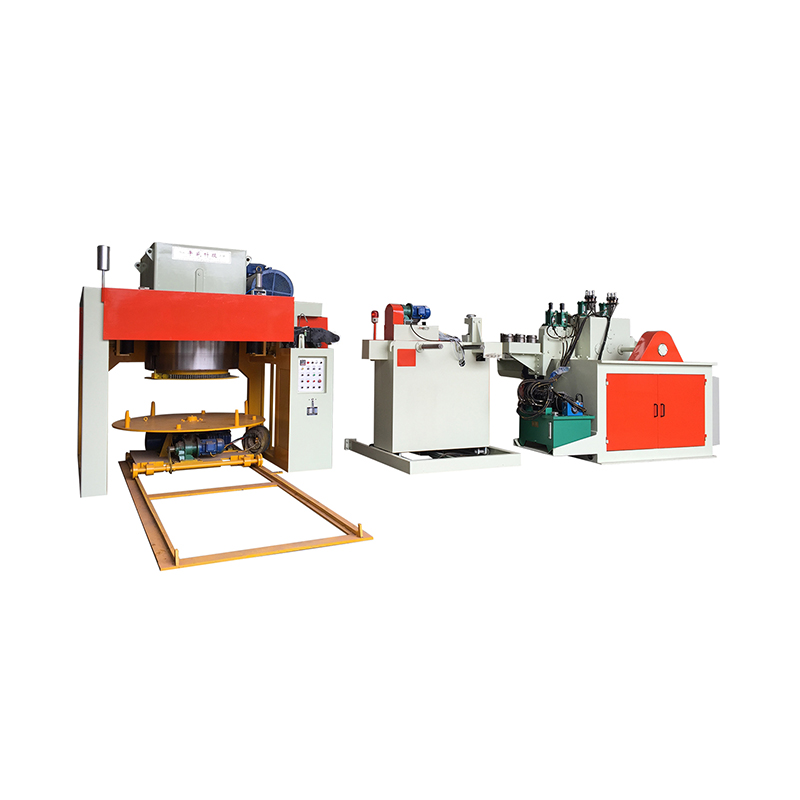

The direct twistless wire drawing machine and the twistless roving wire drawing machine are respectively composed of a winding head, a wire laying device, a wire laying off device, a barrel changing device, an oil mist lubrication device, a pneumatic device, a spray device, and a head brake device. In iuncturam inter fusum machina caput et apparatus caput corpus adoptat a conica meshing positioning ponere in gyrationis accurate de apparatus caput.

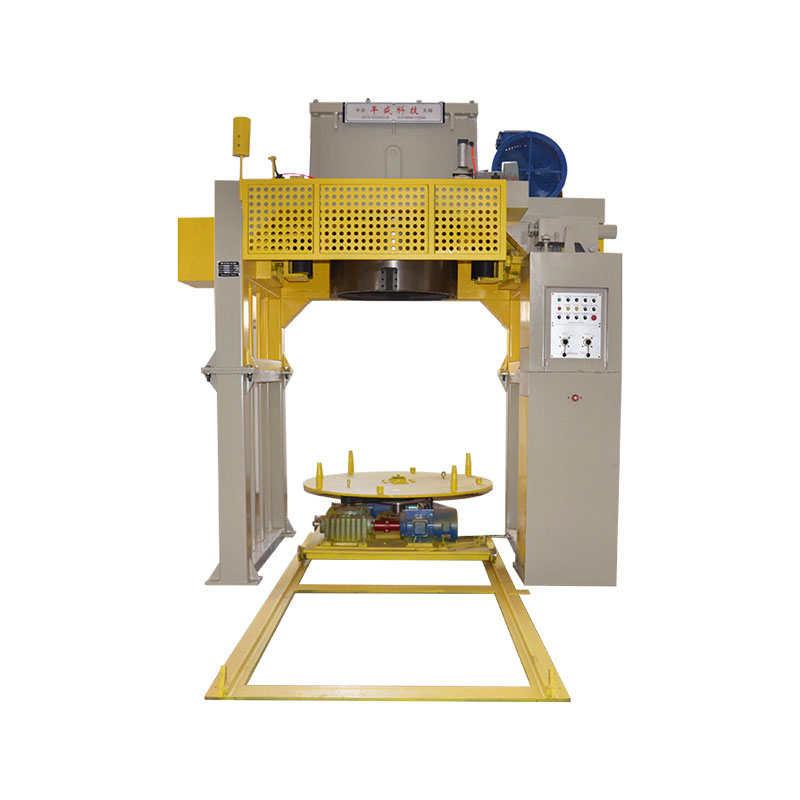

In capite structuram est centrifuga expansion obstructionum type, constans in capite corpus, expansion obstructionum, expansion obstructionum clavem, pressura vere, caput fronte operimentum, et caput tergum operimentum. Tota apparatus caput est de Aluminium Alloy et immaculatam ferro materiae. Cum apparatus capite rotat ad altum celeritatem, expanding obstructionum sustinet curva tympanum sub actionem centrifugal vis, et fibris sunt involvit circa superficiem flumina tympanum. Cum curvis perficitur et apparatus capite sistit rotating, centrifuga evanescit et expanding obstructionum cadit gratis ad unload cylindri.

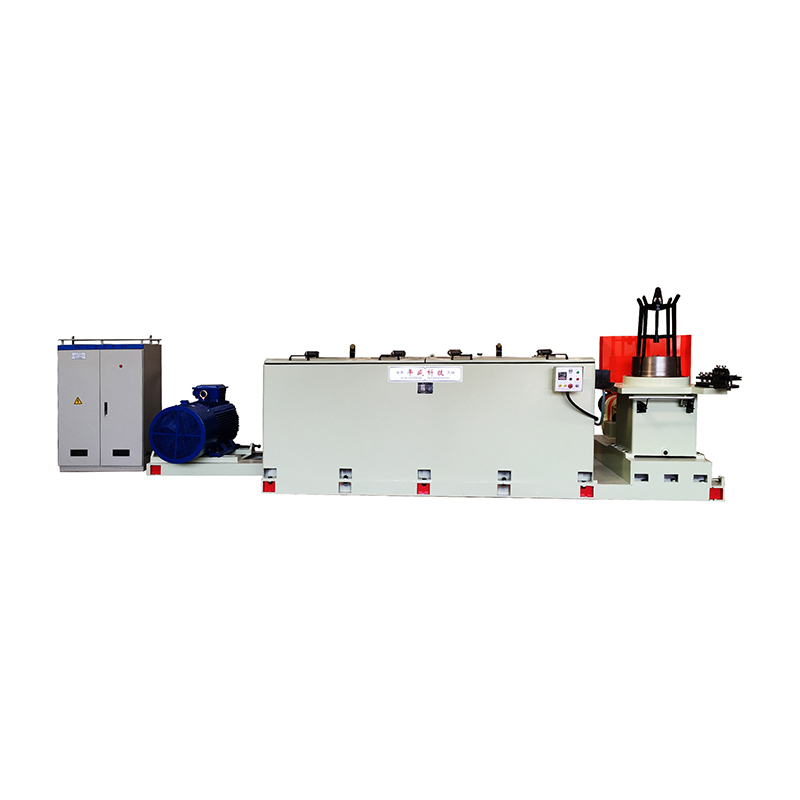

The motion of the spiral steel wire cable shaft of the wire drawing machine is divided into rotational motion and reciprocating motion: the rotational motion is achieved by the cable motor through synchronous belt transmission, and the reciprocating motion is achieved by the servo motor through synchronous belt, rolling screw component, and linear bearing transmission. Reciprocating plaga inter 50-200mm et mutantur positio duo terminum sensoriis potest adjust reciproco plaga.

Functio derailment fabrica untwisted eripere machina duplex: primo movere derailleur versus apparatus caput in principio curngens; secondly, to gradually move the derailleur to the right during the winding process with the extension of time and the increase of the thickness of the silk cake, so that the distance between the wire and the surface layer of the silk cake remains constant, and the tension between the inner and outer layers of the silk cake is consistent.

Tympanum mutans fabrica filum trahens apparatus est coniunctim repulsi per tympanum mutans motricium et cylindri rotate ad opportune curva positus. Motor agit rotating frame rotor per reductionem calces et torquem ad locum deprehendatur sensorem machinae capitis deprehenderit subsisto; Tum positioning cylindri rotating frame activated, causando rotor rotating frame ad Rotor ad designatur positus firmiter Fibulae subsisto obstructionum ut normalis progressus filum trahens operationem.

Pneumaticae fabrica directe untwisted drawing apparatus et untwisted devotio drawing machina consistit de aere pressura switch, aer pressura regulantes valvae, an electro, quod actuus cylindrum, et electromagneticas, quod actuus cylindri et pneumaticorum. Electromagnetic industria consummatio braking est non-contactus et frictionless braking. Altum braking torque et certa operatio. Initibus ad DC potentia post voltage reductionem et rectificationem in stator curvis motricium, ita generating electro torque contrarium rotatione directionem ad consequi electro industria consummatio braking.

Et imbre fabrica in filum trahens machina includit filum-impositis imbre et caput-mutans imbre. Fere-impositis imbre est atomize dionized aqua in diameter 5-10 μ m et imbre per proximos tangentem directionem COLLUM. Functionem imbre fabrica est mundare torto filum et ne conjunctiva madefecissem agentis ad torto filum. Caput-mutantur imbre est solebat ne lane ex cadit in curvis tympanum quando mutantur in tympanum.

En

En